Stabilization of PCR-resin blends for performance applications

- Kevin Lifsey

- Mar 7, 2024

- 9 min read

By Derek Wasylenko, Ph.D., research scientist-Additives; and

Tony Tikuisis, team leader-Additives & Product Safety, NOVA Chemicals Corp.

Abstract

There is increasing interest within the polyolefins value chain to integrate post-consumer recycled (PCR) resins into packaging, driven by consumer sentiment, brand-owner sustainability targets, and regulatory legislation. Additives technologies are routinely used in virgin polyethylene (PE) resins to augment stability, physical properties, or processing; however, high levels of PCR blended with virgin polymers requires additional considerations. Because PE-PCR feedstocks are obtained from consumer products intended and designed for single-use applications, PCR blends require supplementary stabilization to withstand the demands of performance-packaging applications. This article will discuss these factors and strategies that can be used.

Introduction

There is increasing interest within the polyethylene (PE) value chain to integrate mechanically recycled resins into packaging and consumer goods. Many leading brand owners have set goals to use post-consumer recyclate (PCR) within their packaging and consumer goods; on average, these brands have set targets of 25% recycled content in their packaging by 2030 [1]. [AS1] [DW2] To put this into perspective, in 2018 the US containers and packaging sector accounted for about 164 billion lbs of plastics consumption annually [2].

Citizen activism has also placed pressure on governments to mandate restrictions or set targets for recycled content for certain plastic items. To achieve these recycled-content objectives, the plastics industry as whole (i.e.: resin producers, resin converters, brand owners, consumers, and recyclers) will need to work collaboratively to ensure that “circular economy” goals are realized.

In this article, we will discuss the need to incorporate supplemental stabilization to PCR blends to minimize degradation during extrusion (i.e.: melt flow, color stability, and odor generation) to enable the use of the PCR-blend resins in performance-packaging applications.

Polyethylene PCR resins suitable for use in sensitive applications requiring a US Food and Drug Administration (FDA) letter of non-objection (LONO), such as food packaging, are in limited supply [3]. Part of the reason is that it remains difficult to source sufficiently pure PE-based PCR resins, and the most abundant and suitable feedstock currently available is derived from high-density PE (HDPE) blow-molded milk jugs (see Figure 1). Because these milk jugs are designed for a single use before being placed in a recycling bin, the additive stabilization packages used for the resins are often also intended for a single conversion. As a result, the recycled-HDPE PCR pellets aimed for incorporation back into the packaging stream will generally require additional stabilization considerations to meet the demands of high-performance packaging applications. However, before the stabilization requirements of the PCR material are assessed, the polymer itself must be fully evaluated.

PCR evaluation

Our scientists and engineers have developed a process to evaluate PCR resins through a comprehensive stage-gated process to ensure the materials are of sufficient quality before they are blended with our products. Indeed, although the PCR materials being evaluated are ostensibly almost entirely polyethylene, a product that we are very familiar with, it is nonetheless treated as a new material and put through a new chemical review process. For all materials, this process is initiated with an administrative review, where the Safety Data Sheets (SDS), and any other Technical or Product Data Sheets are examined in detail to ensure all the necessary internal and legislative requirements are met, so that there is thorough understanding of the material before allowing it to be used at the various manufacturing and research sites. In addition, each research or manufacturing site has its own independent new chemical review process, reflecting the different activities that occur at these sites and their correspondingly different safety considerations. In many cases, the PCR resin also must be suitable for food-contact applications, and therefore, requires an additional review process to ensure it meets FDA requirements for the intended application.

FIGURE 1. Currently HDPE milk jugs[AS3] [DW4] represent the predominant feedstock available for FDA-approved, PE-based PCR resins.

After completing the administrative review, the PCR resin is then subjected to a small-scale (i.e.: <5 kg) analytical evaluation. This stage involves techniques to evaluate the basic properties of the polymer (rheology, molecular weight, density); a quantification of any contaminants such as polypropylene (PP) or polyethylene terephthalate (PET), and trace elements (metals); and also an assessment of any easily extractable or volatile organic compounds (VOCs) that might be present or released at various temperatures.

If no significant issues are identified through the analytical evaluation, the resin is then subjected to small-scale processing evaluations, either on its own or as blends with virgin resins, using various extrusion and converting equipment. This often includes a multiple-pass extrusion study to understand the behavior of the resin during processing; this also allows an assessment of the stabilization requirements of the PCR material or blends. Note that multiple-pass extrusion studies are conducted using a small-scale, twin-screw extruder and are intended to simulate commercial-scale extrusion (typically 2-3 passes are considered representative for most converter applications). This evaluation could involve a basic assessment of the resin in the intended application, for example, through a small-scale, monolayer blown- or cast-film study, or through various molding processes such as injection, compression, or rotational molding. During this stage, emissions are monitored to ensure no significant odors or VOCs are encountered. It is during this phase of evaluation that additional stabilization requirements are considered.

Stabilization of PCR blends

Before discussing stabilization strategies for PE-based PCR and PCR blends, it will be instructive to first briefly review the additives used for stabilization of polyethylene and their limitations.

Primary antioxidants, as their name implies, are arguably the most important stabilizing additives and are used to ensure adequate long-term and thermal stabilization of the polymer over the course of its lifetime. These additives are based on phenol-containing molecules, and function by sacrificially reacting with high-energy chemical species (known as radicals) that are generated throughout the entire useful life of the polymer, including during production, storage, conversion, and over the lifetime of the finished good (whether disposable packaging or durable product).

As with most things, too much of a good thing can result in problems. In the case of primary antioxidants, an excessive dose of primary antioxidants can lead to processing discoloration, gas fading issues [4], and potential for build-up on processing equipment and finished films or molded parts, that can in turn lead to other problems. FDA limits for phenolic antioxidants are relatively high, so the typical concentration ranges used do not necessarily pose a regulatory concern, as other issues (color) are likely to arise first.

The purpose of secondary antioxidants is mainly to stabilize the polymer during processing by preventing the unnecessary and rapid depletion of primary antioxidants to ensure they are present to protect the long-term stabilization of the polymer. Based on phosphite molecules, these stabilizers readily deactivate peroxides, which are intermediates that rapidly decompose to form more reactive radical species, that in turn react with the primary antioxidants.

Similar to primary antioxidants, excessive doses of secondary antioxidants can lead to issues, in this case related to plate-outs and build-ups on finished articles or processing equipment. However, unlike primary antioxidants, most common secondary antioxidants have relatively low FDA limits [5]. Note that FDA limits apply to not only the active form of the antioxidant, but also to the consumed or oxidized form of the molecules; and because FDA limits for secondary antioxidants are generally lower than primary ones, this presents a challenge when supplemental addition of secondary antioxidants is required for PCR blends.

TABLE 1. Common primary and secondary antioxidants used in PE and their FDA limits

Antioxidant CAS No. | Type | FDA Limits Conditions of Use |

2082-79-3 | Primary | 0.3% |

6683-19-8 | Primary | 0.5% |

31570-04-4 | Secondary | 0.2% |

939402-02-5 | Secondary | 0.2%, A-H |

Stabilization strategies

The first strategy discussed herein to deal with stabilization of PCR blends is to use a virgin resin formulated with a robust antioxidant package. In this scenario, the relatively high level of stabilizing additives present in a virgin PE resin can accommodate the low or depleted levels of antioxidants present in the PCR material (see Table 1). As demonstrated in the multiple-pass extrusion experiment shown in Figure 2, the use of the robust stabilization package does indeed result in a more stable polymer melt, with significantly lower rates of degradation, manifested here as cross-linking and reductions in melt flow index (MFI) over the extrusion passes.

Clearly, the main benefit of this approach is that no additional stabilization may be required for the PCR blends. The one drawback would be that there is reduced freedom to add supplemental stabilizers if the PCR resin has high levels of residual or depleted antioxidants, or the process indicates additional stabilizers may be required.

TABLE 2. LLDPE stabilization formulations used in the multiple extrusion pass studies with 25% HDPE PCR

Stabilization Package | Primary AO (ppm) | Secondary AO (ppm) | Specialty AO 1 (ppm) |

Conventional 1 | 300 | 1,100 | - |

Robust Strategy 1 | 1,800 | 1,700 | - |

Conventional 2 | 500 | 500 | - |

Ternary Strategy 2 | 500 | 750 | 500 |

A second strategy would be to used blends of various antioxidants to overcome FDA restrictions, solubility limits, and other issues that may arise from high individual additive levels. As shown in Table 2, this approach uses a ternary blend with a specialty antioxidant, resulting in lower specific antioxidant concentrations, while still ensuring satisfactory stabilization of the polymer with higher overall levels of antioxidants. In this example, the performance benefits are evident through lower rates of change in MFI over the multiple extrusion passes relative to conventional package 2 (see Figure 3). The key benefit of this strategy would be that supplemental antioxidants could easily be used if additional stabilization was required, with less concern for the issues described above associated with high concentrations of individual additives (i.e.: FDA restrictions and solubility limits).

FIGURE 2. Multiple extrusion pass study with stabilization packages indicated in Table 1 with a twin-screw extruder conducted at 250o C. using a butene comonomer LLDPE with 1.0 melt flow index (MFI) resin (gm/10 min with 2.16 kg @ 190o C.) and 25% HDPE PCR.

FIGURE 3. Multiple extrusion pass study with stabilization packages indicated in Table 2 with a twin-screw extruder conducted at 250o C. using an octene comonomer LLDPE with 1.0 melt flow index (MFI) resin (gm/10 min with 2.16 kg @ 190o C.) and 25% HDPE PCR.

Organoleptic-sensitive applications

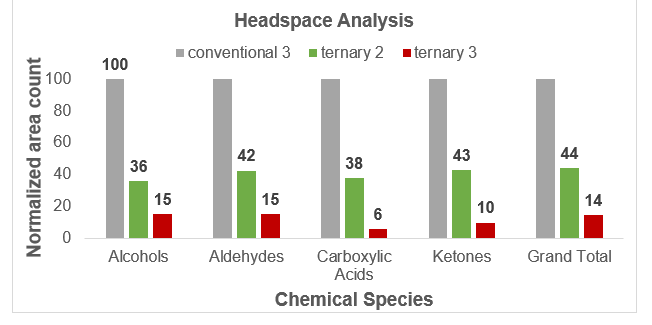

In addition to the benefits described above with the ternary antioxidant stabilization formulations, other benefits may manifest in certain applications. For example, a similar approach was used for an organoleptic-sensitive application, where the specialty antioxidants were able to dramatically reduce the VOCs detected in a headspace evaluation. In this study, 30% HDPE PCR was melt-blended with 70% virgin HDPE and the samples heated in a sealed vial followed by analysis of the volatile species detected (see Table 3).

TABLE 3. Stabilization formulations for melt-blends of virgin HDPE with 30% HDPE PCR subjected to elevated temperatures for a headspace evaluation

Stabilization Package | Primary AO (ppm) | Secondary AO (ppm) | Specialty AO 2 (ppm) | Specialty AO 3 (ppm) |

Conventional 3 | 350 | 700 | - | - |

Ternary 2 | 350 | 1,000 | 500 | - |

Ternary 3 | 350 | 1,000 | - | 500 |

As shown in Figure 4, reductions in VOCs by as much as 64% and 86% were achieved using ternary blends of two different specialty high-performance antioxidants, suggesting lower amounts of these species present in the polymer and correspondingly less potential impact to taste and odor.

FIGURE 4. Evaluation of VOCs generated at 230o C. for 10 mins from a 30% blend of PCR with virgin HDPE using stabilization packages described in Table 3.

In the final stages of our research and evaluation, the PCR materials would be used in a similar manner to how our customers may use them. In the case of films, this may involve multilayer-coextrusion studies using blends and structures that might be suitable for a customer’s applications. These blends often use the robust or ternary stabilization packages described above to enhance the stability of the overall resin blend to ensure satisfactory performance.

Conclusion

There are numerous considerations when using PCR resins and blends within existing packaging and product streams at the scale required to meet brand-owner sustainability goals. Much of the focus is understandably placed on economics, supply, and final product design and performance, but as described herein, attention also must be given to properly formulate PCR blends for their intended functions, where the nature of PCRs resin poses unique challenges.

References

1. New Plastics Economy Global Commitment, June 2019 Report; The Ellen MacArthur Foundation, June 2019; accessed Nov 17, 2020, https://www.newplasticseconomy.org/about/publications/global-commitment-spring-report

2. Facts and Figures about Materials, Waste and Recycling, US EPA, accessed Nov 17, 2020, https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/containers-and-packaging-product-specific-data

3. Guidance for Industry: Use of Recycled Plastics in Food Packaging (Chemistry Considerations), US FDA; accessed Nov 18, 2020, https://www.fda.gov/regulatory-information/search-fda-guidance-documents/guidance-industry-use-recycled-plastics-food-packaging-chemistry-considerations

4. Gas Fading Discoloration of Polyethylene Resins, Waldie, F; Tikuisis, T.; 2017 AIMCAL R2R USA/SPE FlexPackCon®.

5. Title 21 of the US Code of Federal Regulations (21CFR) Parts 175, 176, 177, and 178; US FDA; accessed Nov 17, 2020, https://www.fda.gov/food/packaging-food-contact-substances-fcs/list-indirect-additives-used-food-contact-substances

Derek Wasylenko, research scientist for NOVA Chemicals’ Additives Technology (Calgary, AB, Canada), holds a Ph.D. in Chemistry from the University of Calgary. Prior to joining NOVA Chemicals in 2016, he was a post-doctoral fellow at the University of Washington in Seattle, and worked at a startup in Calgary, developing catalyst materials for industrial applications. In his current role, Derek is responsible for evaluating new additive-based technologies for PE applications, developing formulations for products in a variety of markets, expanding fundamental understanding of additives in PE applications, and customer support for additives-related topics. He can be reached at 403-291-8175, email: derek.wasylenko@novachem.com, www.novachem.com

Tony Tikuisis, additives technology and product safety team leader at NOVA Chemicals’ Centre for Performance Applications (Calgary, AB, Canada), obtained an Honors Bachelor of Science in Applied Chemistry from the University of Waterloo in 1984. He joined NOVA Chemicals in 1985 (then Novacor Chemicals, Ltd.). The additives team uses additive technology to enhance PE-product performance, while the product safety team is responsible for product regulatory compliance, hazard communication, and product stewardship. Tony has co-authored several additive-related presentations and publications and holds numerous PE-additive application patents. He can be reached at 403-291-8475, fax: 403-291-0493, email: tony.tikuisis@novachem.com

Comments